Featured Initiatives

By investing in our operators & tradespeople training, new equipment and technological improvements, AV Terrace Bay is paving the way towards exceeding production goals for this year.

We’ve been hard at work reinvesting and streamlining processes to ensure maximum value for our stakeholders, clients and strategic partners.

We are tightening our procedures and are proud of our recent track record - Zero Lost Time Industrial Accidents 2013 to Present.

AV Terrace Bay Toxic Reduction Plan and Accounting Summary and Technical Standard TRS Reduction Implementation & Performance is available on request.

AV Terrace Bay is committed to increase its community involvement and creating long lasting partnerships.

AVTB continues to focus on sustainability and environmental responsibility and embarks on the third phase of the process control (DCS) automation plan.

AVTB continues to focus on sustainability and environmental responsibility and embarks on the third phase of the process control (DCS) automation plan.

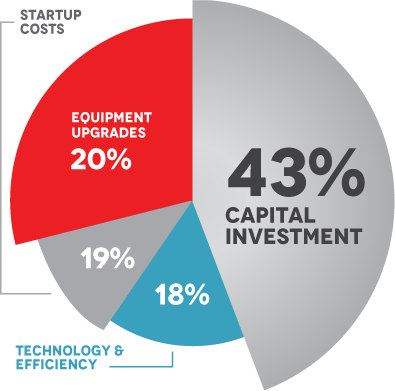

Equipment Upgrades

These consisted of new wood yard equipment, new rail wagons, and major overhauling of dated equipment.

Improving Reliability

Improving mill reliability is a direct result of timely and accurate diagnosis of equipment supported by precision maintenance practices.

Capital Investments

Includes ongoing investments in the mill. Working capital investments have significantly improved overall operations.

Technology Upgrades

DCS and mill-wide instrument upgrades have been completed which significantly improves the operation efficiency.

Improving Efficiency

Increasing operational efficiencies and an improved mill output through automation and better data integration.

Startup Investment

Roughly $29 million invested to cover investment in workforce and operations to start up the mill.

With increased stability comes the opportunity for enhanced community engagement. AV Terrace Bay will dedicate resources to increase community involvement and presence. With a new Community Advisory Board in development, this board will be working with local municipalities to further develop tourism, arts, culture, sport, volunteerism, and economic development in and around Terrace Bay.

We are aggressively targeting talent by strengthening collaboration with colleges in Thunder Bay, North Bay, Sault Ste. Marie and Timmins to help expand our hiring pool and increase attendance in our Junior Apprenticeship program.

With a renewed set of goals focusing on increased involvement in our surrounding communities, we are creating the foundation for increased participation in a variety of community ventures.

As part of our commitment to sourcing sustainable sources of fibre, AV Terrace Bay has partnered with First Nations’ owned Mkwa Timber.

With the second phase of announcements from the provincial government, forestry continues to be an essential service. Specifically to our mills, our products are utilized to produce tissue products, paper towel and cleaning products, medical supplies including masks, disinfectant and sanitary wipes, hygiene products, diapers, etc through our partner downstream manufacturers.

Darin Guzzell, Manager – Human Resources at AV Terrace Bay Inc. stated, “On behalf of the Aditya Birla Group of Companies and the more than 400 hardworking employees who continue to produce Northern Bleached Soft-Wood Kraft (NBSK) grade pulp, AV Terrace Bay is proud to contribute a total of $50,000 (fifty thousand dollars) divided amongst the McCausland Hospital for the purchase of PPE for the frontline workers, to the local Meals on Wheels Program, and to the North Shore Harvest Cupboard.”

Guzzell added, “Each of these worthy causes provide services for the communities of Jackfish, Terrace Bay, Schreiber, Rossport, and Pays Plat. These are our neighbours, friends, and colleagues. We are all in this together and we are honored to assist in any way possible.” Additionally, $10,000 were donated in December’2020 to the North Shore Harvest Cupboard.